Our Services

Our Sales and Services staff are professionally trained and certified by our principal's offices to ensure high quality solutions and services always for our customers.

Our Services Team is successfully delivering several projects annually since 2015 related to Industrial Combustion Systems of varying size, nature, and challenges, including Annual Maintenance Contracts.

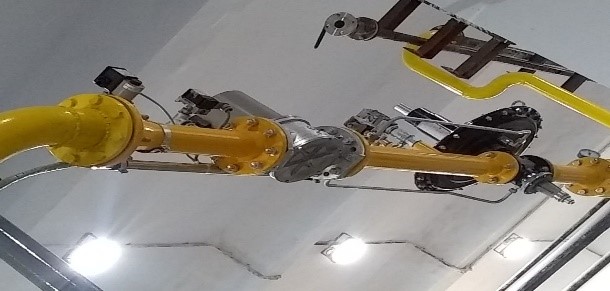

Installation & Commissioning of Industrial Burners

-

Site survey and problem diagnosis

-

Burner / Spare parts selection

-

Air-fuel ratio adjustment

-

Electrical and safety system checks

-

Flue gas monitoring

-

Performance monitoring

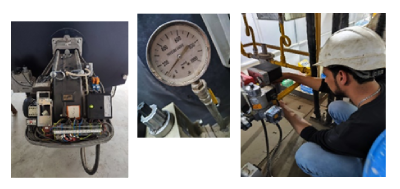

Installation & Commissioning of Gas Trains

-

Site survey & Relevant Data Collection

-

Gas Train Components Selection based on collected data.

-

Commissioning of Gas Train Components.

-

Fine setting of output pressure and safety components

-

installed on gas train.

Tuning of Industrial Burners

-

Burner sequencing checks

-

Burner sequencing checks

-

Air-fuel ratio adjustment

-

Post tuning flue gas monitoring using analyser.

-

Electrical safety system checks

-

Efficiency enhancement

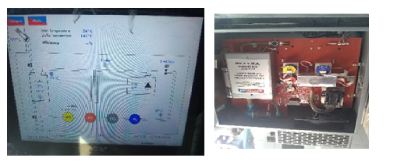

Installation & Commissioning of Autoflame BMS

-

CMS PLC & hardware selection based on customer’s requirement.

-

Installation & Commissioning of CMS along with relevant components.

-

Installation & Commissioning of Boiler Controls [water level, TDS, BBD,

draft control] etc. -

Firmware Software upgradation.

-

Programming of all Options/Parameters based on Boiler Specs.

-

Air-Fuel Curve Commissioning & Adjustment.

-

Load output and Burner Management parameters adjustment.

-

Enhanced combustion efficiency and boiler controls.

Installation & Commissioning of Controllers

-

Selection of PID controller as per application.

-

Programming of parameters as per site hardware & requirement.

-

Installation on site and process monitoring.

& -

Selection of Burner Controller based on Mono Block burner type.

-

Programming of options/parameters based on application and burner hardware.

-

Installation on site and burner sequence monitoring

Exhaust Gas Analysis Services

-

Exhaust Gas Analysis using flue gas analyser.

-

Flue Gas analysis output parameters check as per ISO standards.

-

Adjustment strategy based on Flue gas output report & ISO standards.

-

Air-Fuel ratio adjustment via gas train or burner hardware.

-

Post tuning flue gas monitoring using analyser.

-

Improved combustion efficiency & gas savings.

Installation & Commissioning of Autoflame Exhaust Gas Analyzer [MK8 EGA EVO]

-

Relevant Flue Gas Sensors Selection as per fuel and customer’s requirement.

-

Autoflame MK8 EGA EVO Installation on site.

-

Merging of MK8 EGA EVO with Autoflame BMS System.

-

Relevant Options/Parameters programming.

-

Auto trimming calibration of air-fuel ratio.

-

Attainment of maximum combustion efficiency with 24/7

flue gas monitoring and auto trimming ratio control.

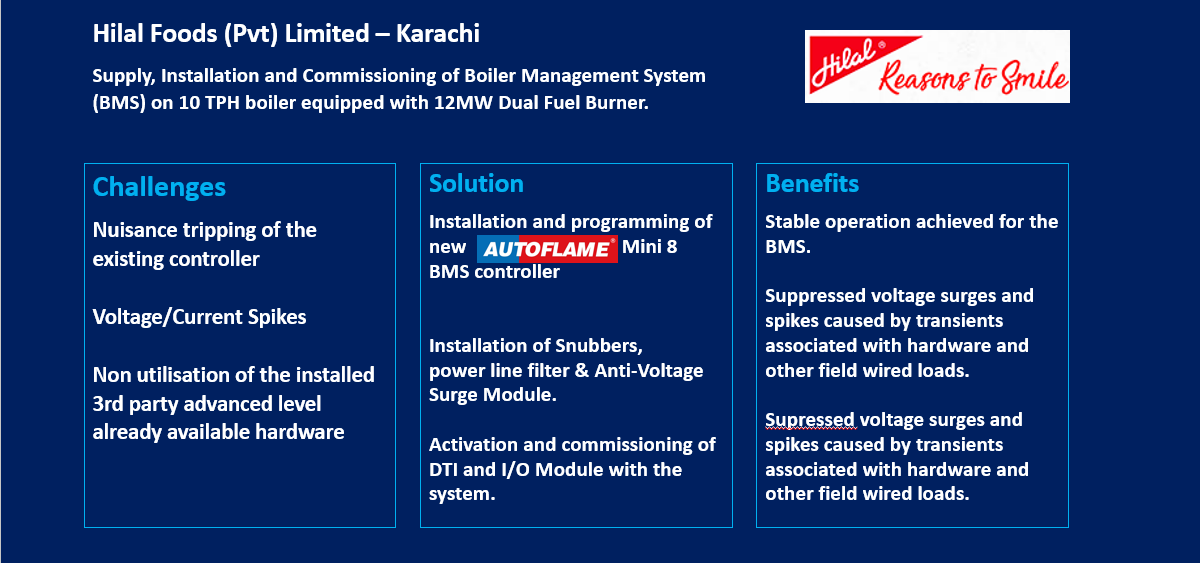

Customer Success Stories

Our Services team successfully undertake several projects on Industrial Combustion Systems of varying size, nature and challenges each year, including Annual Maintenance Contracts. Selected project references are as below:

International Textile Ltd

Installation & Commissioning of Autoflame MK8 MM in replacement of Lamtec System at International Textile Limited on 16TPH Natural Gas Boiler.

Midas Safety

Tuning of all Natural Gas Burners [different capacities varying from 150kW to 4.5MW totalling to 94 burners] installed at Midas Safety.

Lucky Textile Mills Ltd

Tuning of Natural Gas Burners installed on different Stenter Machines [totalling to 56 burners ranging from 300 to 900kW] at Lucky Textile Mills Limited.

National Foods Ltd

Selection, Installation & Commissioning of Gas Trains for LPF Fuel I-Type Burners, for vegetable oil heating application at National Foods Limited.

Volka Foods Ltd

Tuning of 03 Dual Fuel Burners ranging from 900 kW to 6.2 MW [NG & LPG] installed on hot water boilers at Volka Foods Limited.

Yunus Textile Mills Ltd

Supply & Commissioning of Main Gas Train for 4.5 MW Power Generation Engine installed at Yunus Textile Mills Limited.

Popular Fabric Mills

Supply, Installation & Commissioning of 24 High Turn Down Ratio Burners [up to 350kW] on Stenter Machines installed at Popular Fabrics Mills.

Ayesha Steel Mills Ltd

Tuning of 03 Boilers each of 6TPH equipped with 5.2MW UniGas Natural Gas Burners.

Hossana Textile

Supply, Installation & Commissioning of Autoflame MK8 MM CMS along with Water Level Controls, TDS, TBD & Flue Gas Recirculation system on 16 TPH Boiler equipped with 9.1 MW Limpsfield Burner.